Every car enthusiast knows that performance and style go hand in hand. Whether you’re chasing lap times or simply want a cleaner, more refined engine bay, the finish on your components matters. That’s why so many builders and racers turn to Cerekote—a ceramic-based coating engineered to protect and perfect automotive parts under extreme conditions.

At Rvng RaceWorks, we use Cerakote across a wide range of components, from turbo housings to valve covers, to deliver unbeatable durability, heat resistance, and aesthetics. In this guide, we’ll show you exactly where Cerakote makes the biggest impact and why it’s become the go-to finish for high-performance builds.

Why Cerakote Is a Game-Changer for Automotive Components

Cerakote is a thin, ceramic-based polymer coating that provides superior protection against heat, corrosion, and abrasion. Unlike powder coating or paint, it chemically bonds to the surface, forming a durable, heat-resistant barrier that can handle temperatures up to 1,800°F.

Its incredibly thin film—measured in microns—means it doesn’t interfere with tolerances, making it ideal for precision parts. At Rvng RaceWorks, we apply Cerakote to a variety of metal surfaces, ensuring long-lasting protection and a flawless finish that stands up to racing, track days, and daily driving.

Turbo Housings: The Ultimate Test for Heat Resistance

Turbochargers operate in one of the harshest environments under the hood. With temperatures soaring past 1,000°F, traditional coatings quickly fail. That’s where Cerakote shines.

When applied to turbo housings, Cerakote helps manage extreme heat, prevents oxidation, and reduces surface temperatures around the turbo system. This not only extends the lifespan of the housing but can also help reduce heat soak in nearby components.

At Rvng RaceWorks, we use high-temperature Cerakote formulas that withstand continuous thermal stress without peeling, cracking, or fading—making them ideal for both performance and reliability.

Exhaust Manifolds and Downpipes: Conquering Corrosion and Heat

Exhaust systems endure constant exposure to heat cycles, moisture, and corrosive gases. Without proper protection, they quickly rust and degrade. Cerakote creates a ceramic barrier that resists oxidation and corrosion while maintaining excellent heat stability.

By applying Cerakote to manifolds and downpipes, we improve both performance and aesthetics. The coating helps retain exhaust heat inside the pipes, improving gas velocity and turbo efficiency. Plus, it keeps your exhaust components looking clean and professional, even after thousands of miles.

Valve Covers: Combining Function and Style

Valve covers are one of the most visible parts of an engine bay, making them a popular choice for Cerakote customization. At Rvng RaceWorks, we often apply Cerakote to valve covers not just for protection, but to help customers express their style.

The coating’s resistance to oil, fuel, and chemicals makes it perfect for components that see regular exposure to engine fluids. Whether you choose a stealth matte black, metallic titanium, or a custom color to match your theme, Cerakote keeps your valve covers clean and corrosion-free while delivering a stunning finish that lasts.

Intake Manifolds: Performance Meets Precision

The intake manifold plays a crucial role in engine performance, and it’s another perfect candidate for Cerakote. Because the coating is so thin, it doesn’t affect fitment or airflow, yet it offers exceptional heat and corrosion resistance.

By coating intake manifolds, Rvng RaceWorks helps prevent heat soak, keeping intake temperatures lower for more consistent performance. The smooth, sealed surface of Cerakote also makes it easier to clean—just wipe away dirt, oil, or dust without hassle.

Brake Calipers: Strength and Style Under Pressure

Brake calipers face intense heat and constant exposure to brake dust, moisture, and road grime. Over time, even powder-coated finishes can chip or fade. Cerakote provides a long-lasting, heat-resistant finish that stands up to the extreme demands of braking systems.

We apply Cerakote to brake calipers to prevent corrosion, simplify cleaning, and give them a sharp, professional appearance. From race-ready matte finishes to custom gloss colors, Cerakote allows you to personalize your setup while improving durability.

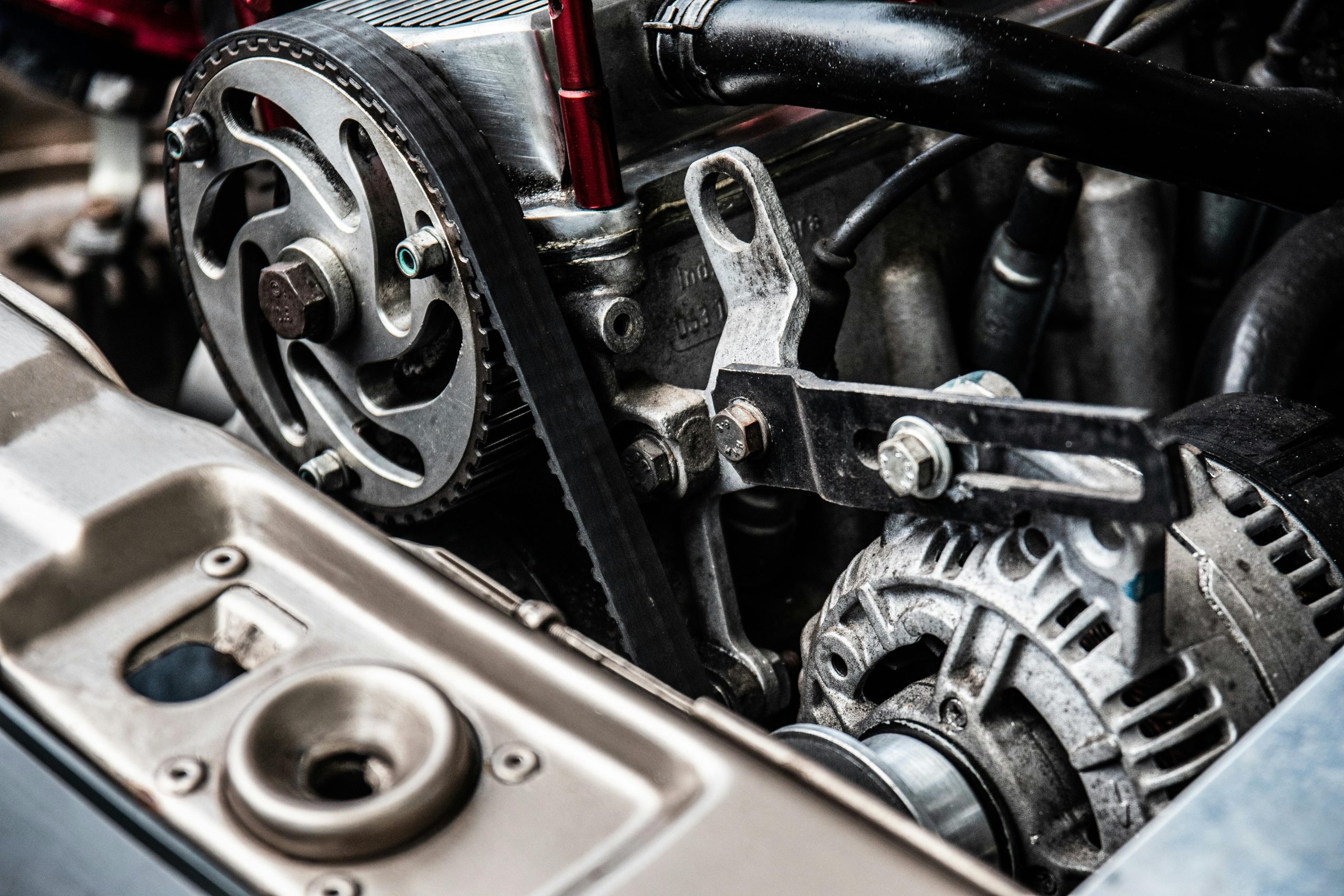

Engine Brackets, Fittings, and Hardware: The Small Details Matter

Every builder knows that small details make a big difference. Brackets, bolts, and fittings may seem minor, but when finished with Cerakote, they complete the look of a high-end build.

These smaller components are prone to rust, especially when exposed to moisture or road salt. A thin layer of Cerakote protects them without adding bulk, ensuring they remain clean and corrosion-free for the life of your vehicle.

At Rvng RaceWorks, we coat even the smallest parts to maintain consistency and quality across the entire engine bay.

Suspension and Underbody Components

Performance doesn’t stop under the hood. Cerakote can also be used on suspension arms, subframes, and underbody components to prevent rust and wear. Its toughness and chemical resistance make it ideal for parts that face debris, salt, and dirt.

The result? A chassis that looks as good as it performs—and lasts much longer than untreated components.

Why Rvng RaceWorks Trusts Cerakote for Every Build

At Rvng RaceWorks, we’ve built our reputation on precision and performance. We choose Cerakote because it delivers results that go beyond surface-level beauty. The coating provides the protection, heat resistance, and custom styling today’s enthusiasts demand.

Each Cerakote application we perform is done with meticulous attention to detail—from surface prep and masking to curing and inspection. The result is a flawless, durable finish that elevates every component it touches.

Whether we’re coating a single turbo housing or a full engine assembly, our goal is simple: long-lasting performance and unbeatable style.

Conclusion

From turbo housings and exhaust manifolds to valve covers and brake calipers, Cerakote has proven itself as the ultimate coating for performance parts. Its heat resistance, durability, and customizable finish make it the perfect choice for any serious builder or racer.